Fujitec Lifts

REXIA

A machine-room-less lift with revolutionary energy saving features, REXIA is trusted by major architects and designers the world over.

ZEXIA

A passenger lift with machine room, ZEXIA incorporates the latest human engineering technologies.

High Rise

A passenger lift with machine room, ZEXIA incorporates the latest human engineering technologies.

Sky Salon

A passenger lift with machine room, ZEXIA incorporates the latest human engineering technologies.

Since the foundation of Fujitec in 1948, seeing the market from a global perspective and having the spirit of being a top global company, Fujitec has been a global leading manufacturer of lifts, escalators, and moving walks. Fujitec has been providing the people with leading-edge technologies and global standards of product.

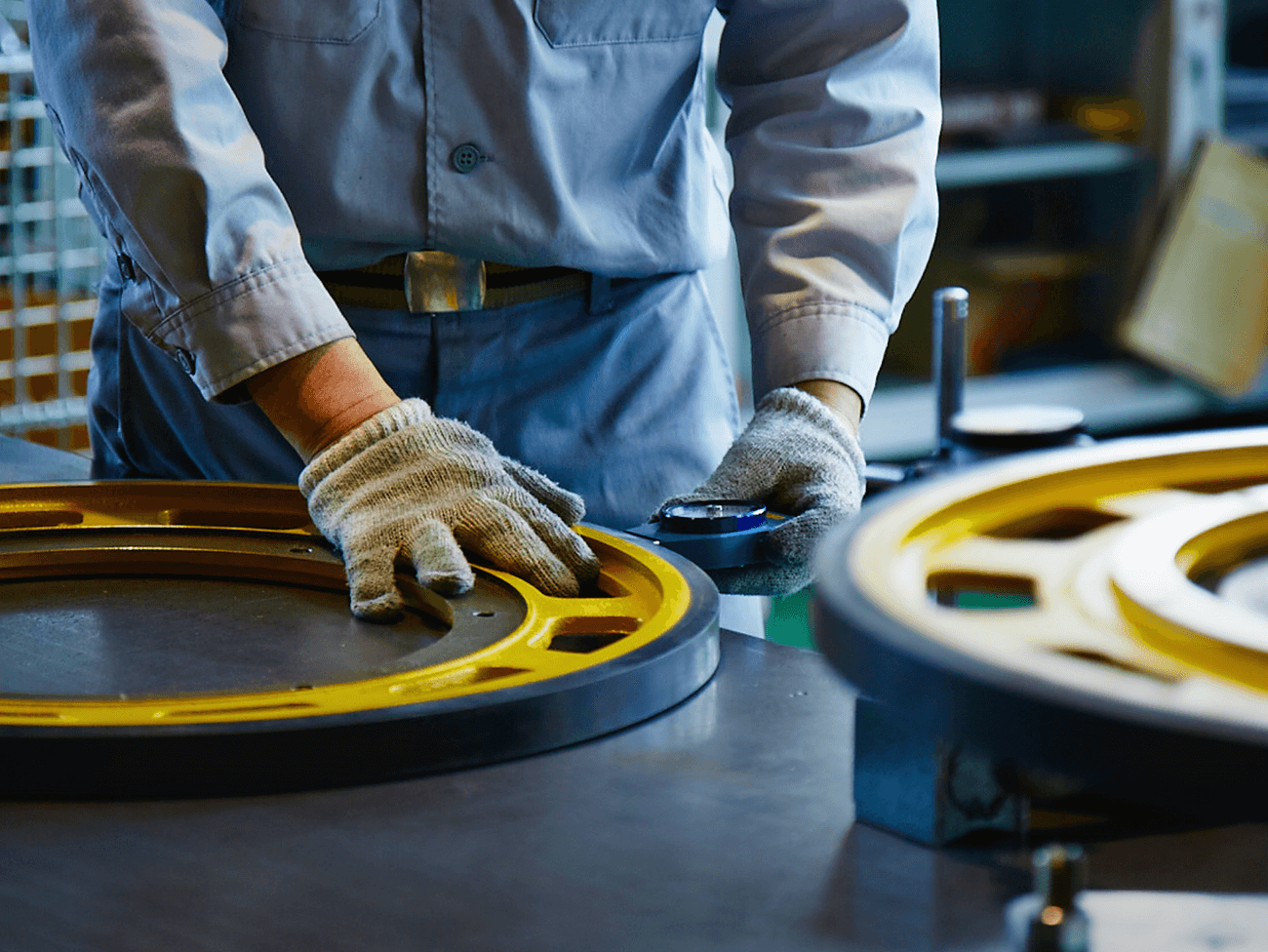

Quality Control

Fujitec’s “Global Common Components” are used in the REXIA brand. The quality of components, such as traction machines, lift controllers and operating fixtures, is controlled through Fujitec’s integrated system of global quality management. Lifts with the same high quality will be provided by Fujitec’s global production base under the concept of “Made in Fujitec”.

Ecology

In ZEXIA and REXIA lifts, gearless traction machines with permanent magnet synchronous motors (also known as Permanent Magnet Gearless machines) assure low power consumption. Also, the electric power regenerative unit equipped between the lift controller and the power supply saves the electrical energy consumption in the building. Fujitec contributes to global society by providing for ecology-conscious products, drawing on its 70 years of knowledge, experience and technologies in manufacturing lifts.

Comfort Design

Under Fujitec’s universal designs, newly adopted buttons for lift operating fixtures are highly visible and tactually recognisable. The numerals and letters shown on aesthetically refined displays can be easily seen and read. Also, various styles for the decoration of lift interiors and landings provide the passengers with a superb and comfortable riding experience

Sustainability

With higher demands on lift performance, especially after the original service life has expired, owners and managers have to meet demand for greater health and safety standards. The average lift replacement cycle is 20 to 25 years. Usually before any full replacement of a lift there is a large repair or modernisation plan to be considered, which would normally take place 15 to 20 years after installation, dependant on usage.

Fujitec units offer a higher life expectancy with a proven track record of 25 to 30 years with minimal to no repairs required, although technology advances do mean that existing lifts can be upgraded in terms of safety, comfort, reliability, energy savings and design. Modernising or replacing old lifts can dramatically reduce the breakdown rate and improve operational performance.

Safety & Reliability

All control-related components ranging from control circuits to inverters are independently developed by Fujitec, so that the lift operation is highly reliable. When the lift control system assembled with Fujitec’s reliable component parts detects the possibility of lift malfunction, it operates to maintain the lift’s stability and efficiency. All Fujitec lifts contain a number of built-in safety features:

Car door Locking

Prevents the car door from opening if the lift is not fully aligned with the floor and protects passengers from falling into the lift shaft.

Impact Resistant Landing Door System

Landing doors are stronger and more impact resistant, thereby protecting passengers from falling into the lift shaft if they accidentally impact with the landing doors.

Unintended Car Movement Protection System

Immobilises the car when the lift and landing car doors are opened but the car is not aligned with the landing floor. Protects against personal injury and equipment damage.

Intelligent Multi-Beam

Detects people, pets and objects to ensure safety when entering or leaving the lift. The protection system projects an infrared ray-light curtain covering the whole door opening height at the lift entrance and if the light beam is interrupted, the closing door will stop closing, and re-open automatically.

Self-Diagnostic Night Operation

Every night, the lift self-diagnostic operation automatically starts to inspect its operation and braking system at each floor.

Re-leveling

In the event of lift failure, the lift will automatically re-level and open the doors to allow a passenger to safely exit the lift car.

Battery Powered Back Up System

In the event of a power cut the lift callout engineer will be able to drive the lift car to the nearest level for safe release of the passenger.